About Us

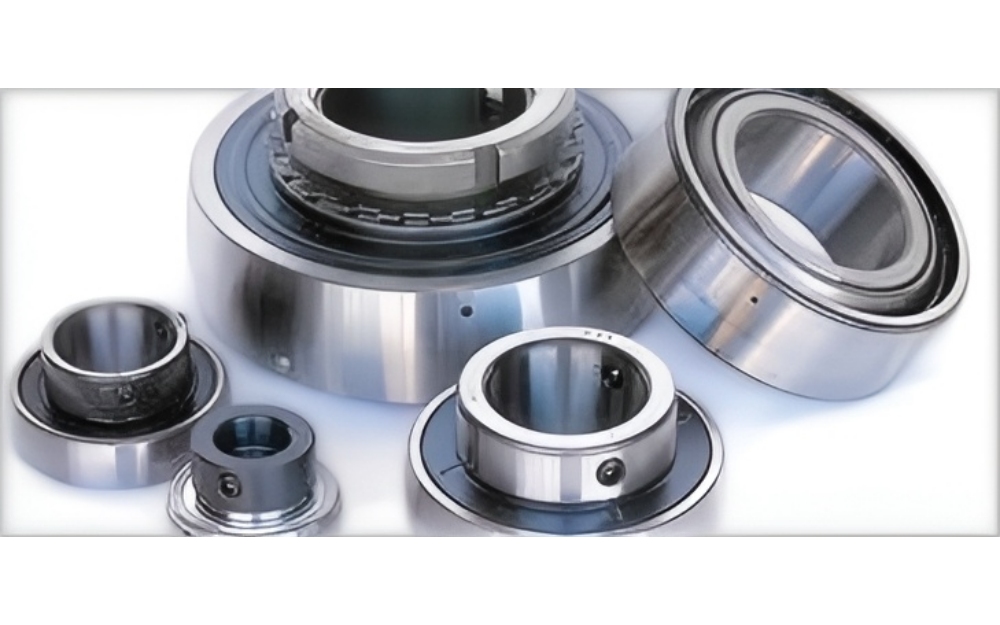

Why can these "look the same" bearings have a price difference of up to 100%?

Views : 13

Update time : 2025-12-26 21:29:00

Many buyers are confused when purchasing bearings for the first time:

"These two bearings look exactly the same, and the models are similar, so why is one priced at 30 and the other at 60?"

The outer diameter, inner diameter, and width are identical, the steel rings are shiny, and even the packaging boxes are similar.

Judging by sight alone, it's indeed difficult to understand the price difference.

However, in the bearing industry, "looking the same" is often just the surface. The real factors determining the price are mostly hidden in places you can't see or touch.

Below, we'll explain where this "double price difference" goes by looking at some of the most easily overlooked yet most impactful details on cost and lifespan.

Different Steel: The Fundamental Factor in Bearing Price Differences

Bearings are metal parts, but it's not simply a matter of "any steel will do."

1. The Invisible Difference: Steel Purity

While higher-priced bearings typically use high-purity bearing steel, with lower levels of impurities such as sulfur and phosphorus.

What's the difference?

1.More impurities → Higher risk of internal microcracks

Higher speeds or heavy loads → More prone to fatigue spalling

Same appearance, but lifespan can differ by more than double.

2. Heat treatment level determines "hard but not brittle"

Truly good bearing steel is not just about being "hard," but about a balance of hardness, toughness, and stability.

This highly depends on the heat treatment process, not just a number in the material specification.

- Bearings with good heat treatment:

- More dimensionally stable over long-term operation

- Less prone to deformation due to temperature rise

- Stronger impact resistance

This cost may not be visible on the quotation, but it will definitely be reflected in the price.

Machining precision: A difference of "a few micrometers," but it can be fatal

Many people believe that as long as a bearing can rotate, the machining is fine.

However, in industrial equipment, "being able to rotate" and "rotating stably and for a long time" are two completely different things.

1. Raceway Precision: Determining Smooth Operation

- High-priced bearings often undergo several additional processes in raceway machining:

- Precision grinding

- Ultra-precision machining

- Stricter control over roundness and waviness

- What are the results?

- Lower noise

- Less vibration

- No "floating" at high speeds

2. Cage Precision: Severely Underestimated

- Can lead to uneven stress on the rolling elements

- Can easily cause overheating at high speeds

Inspection Process: What You Don't See Is the Most Valuable

相关新闻

Why can these "look the same" bearings have a price difference of up to 100%?

Why can these "look the same" bearings have a price difference of up to 100%?

Dec 26,2025

Why can these "look the same" bearings have a price difference of up to 100%?

Deep Groove Ball Bearing vs. Angular Contact Ball Bearing 2025

Deep Groove Ball Bearing vs. Angular Contact Ball Bearing 2025

Dec 19,2025

Deep Groove Ball Bearing vs. Angular Contact Ball Bearing 2025

How do bearings support both light and heavy industries?

How do bearings support both light and heavy industries?

Dec 12,2025

How do bearings support both light and heavy industries?

Abnormal temperature rise and vibration noise: Interpreting early warning signals of bearing housing failure!

Abnormal temperature rise and vibration noise: Interpreting early warning signals of bearing housing failure!

Dec 04,2025

Abnormal temperature rise and vibration noise: Interpreting early warning signals of bearing housing failure!